METHODS MACHINE TOOLS CAN PARTNER

WITH YOU EVERY STEP OF THE WAY.

From selecting and configuring the right

machine for your job to helping you finance the purchase that generates noticeable profits.

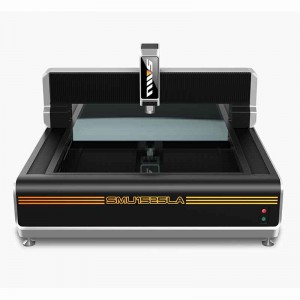

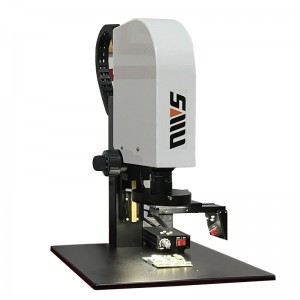

Feature Products

Why

choose us

Chengli is a precision measuring equipment manufacturer brand, which provides a series of precision measuring equipment such as optics, imaging and vision for the global manufacturing industry with the corporate philosophy of self-developed innovation and precision.

Chengli is committed to creating an era of high-precision intelligent measurement from the power of the East. It will serve mid-to-high-end manufacturing industries such as semiconductors, precision electronics, hardware, plastics, molds, and LCD screens.

The brand name “Chengli” is taken from the Chinese philosopher Cheng Yi in the Song Dynasty that “people cannot stand in the world without integrity.” The word “Chengli” is not only the company’s business philosophy, but also represents the company’s quality and external image.