China OEM Non-Contact Optical Measuring Machine – PPG-60403ELS-800KG Automotive power battery thickness measuring machine – Chengli

China OEM Non-Contact Optical Measuring Machine – PPG-60403ELS-800KG Automotive power battery thickness measuring machine – Chengli Detail:

Product Video

Introduction

PPG-60403ELS-800KG is suitable for measuring the thickness of lithium batteries, automotive power batteries and other non-battery thin products. It uses servo motor to provide pressure, so that the product measurement is more accurate.

Operating steps

The specific measurement steps of the high pressure electric PPG battery thickness gauge are as follows:

1. Turn on the power of the machine

2. The machine returns to the zero position and performs height correction

3. Set the measurement procedure (including setting the required measurement force value, measurement thickness and running speed etc.)

4. Put the product into the test platform

5. Start the test

6. Display test data and export reports

7. Replace the next product to be tested

The Main Accessories

1. Sensor: Open grating encoder.

2. Coating: baking paint.

3. Parts material: steel, 00 grade cyan marble.

4. Housing material: steel, aluminum.

Technical parameters

|

S/N |

Item |

Configration |

|

1 |

Effective test area |

L600mm × W400mm |

|

2 |

Thickness range |

0-30mm |

|

3 |

Working distance |

≥50mm |

|

4 |

Reading resolution |

0.0005mm |

|

5 |

Flatness of marble |

0.005mm |

|

6 |

Measurement error of one position |

Put a PPG standard gauge block between the upper and lower pressure plates, repeat the test 10 times at the same position, and its fluctuation range is less than or equal to 0.02mm. |

|

7 |

Comprehensive measurement error |

Place a PPG standard gauge block between the upper and lower platens, and measure the center point of the platen and the dimensions of the 4 corners. The fluctuation range of the measured value of the center point and the four corners minus the standard value is less than or equal to 0.04mm. |

|

8 |

Test pressure range |

0-800kg |

|

9 |

Pressure method |

Use servo motor to provide pressure |

|

10 |

Work beat |

<30 seconds |

|

11 |

GR&R |

<10% |

|

12 |

Transfer method |

Linear guide, screw, servo motor |

|

13 |

Power |

AC 220V 50HZ |

|

14 |

Operating environment |

Temperature:23℃±2℃ Humidity:30~80% |

|

Vibration:<0.002mm/s,<15Hz |

||

|

15 |

Weigh |

350kg |

|

16 |

***Other specifications of the machine can be customized. |

|

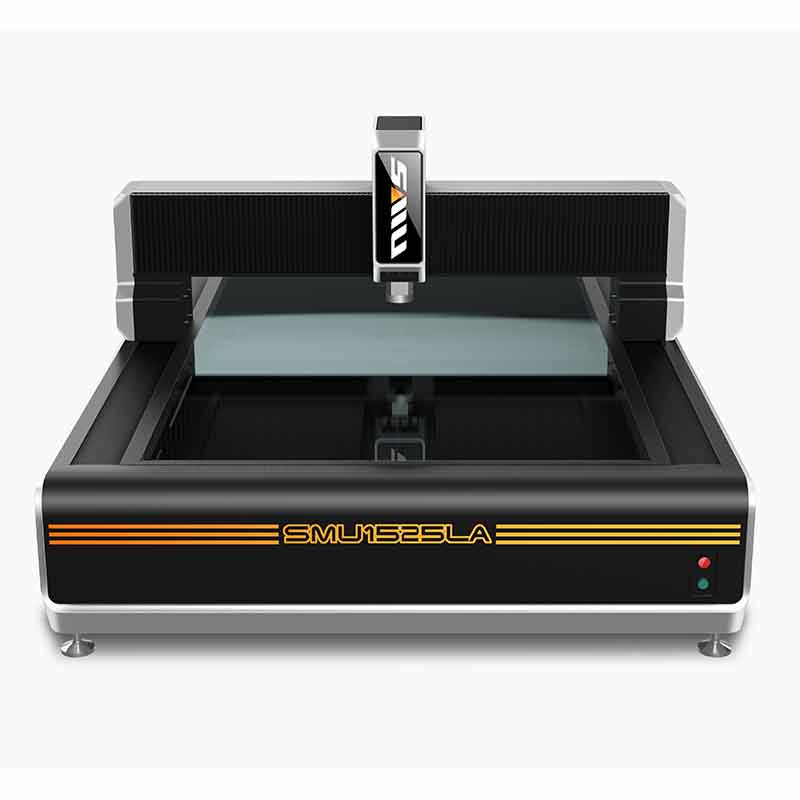

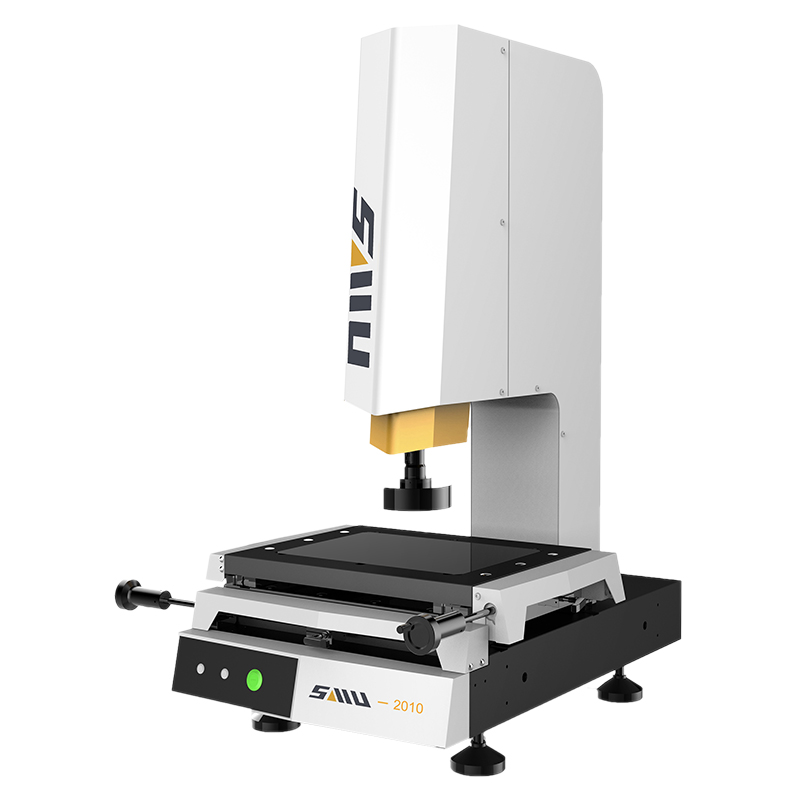

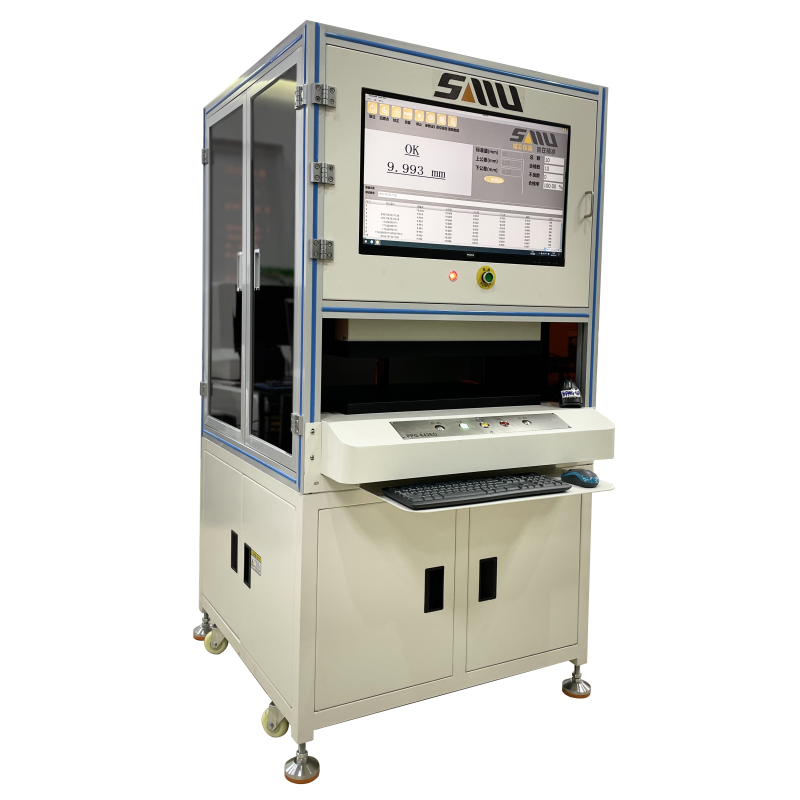

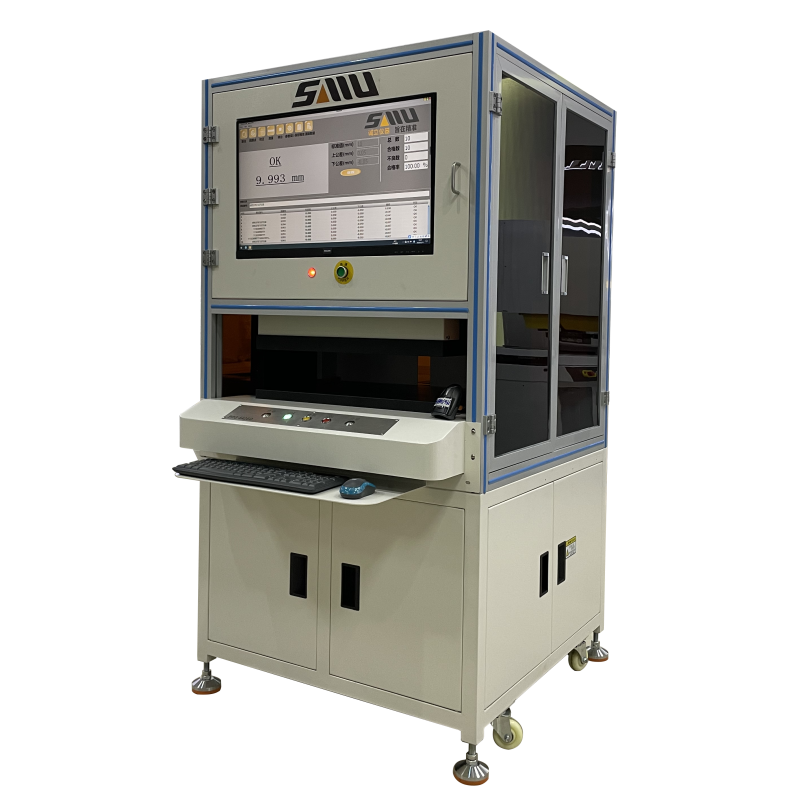

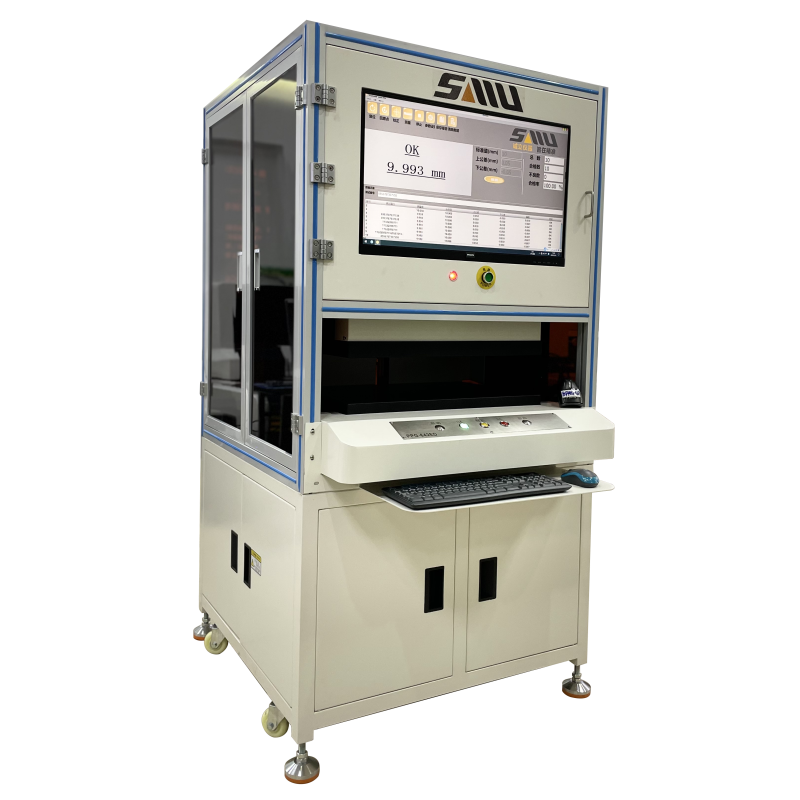

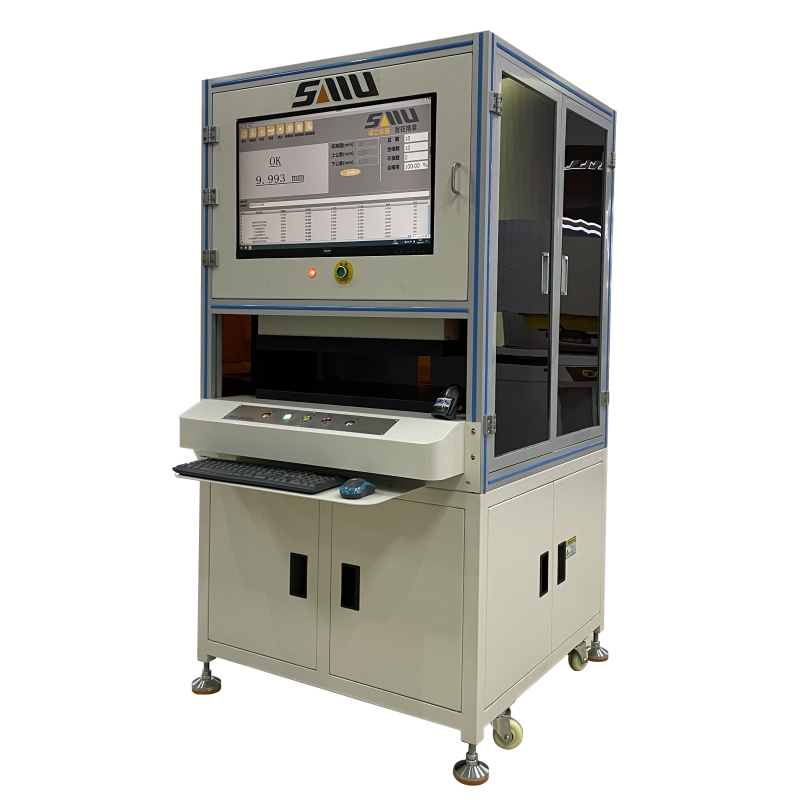

Pictures of the device

Product detail pictures:

Related Product Guide:

We always follow the principle "Quality Very first, Prestige Supreme". We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for China OEM Non-Contact Optical Measuring Machine – PPG-60403ELS-800KG Automotive power battery thickness measuring machine – Chengli , The product will supply to all over the world, such as: Iran, Guatemala, Sydney, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to provide you the best service. If you need more information, please do not hesitate to contact us by E-mail or telephone.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.