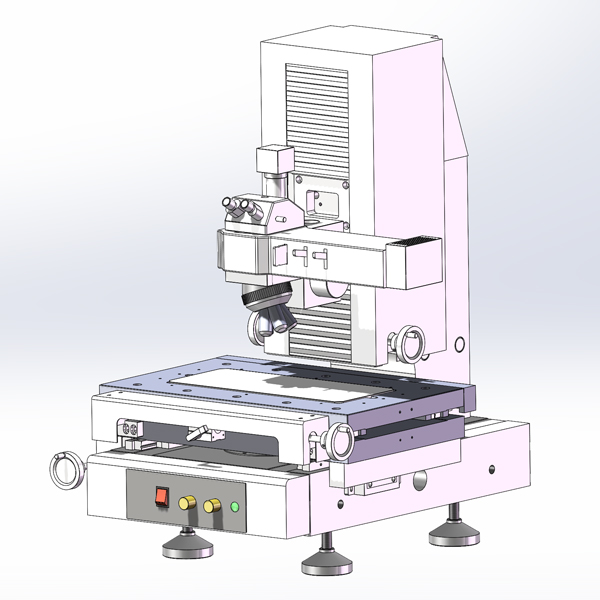

China OEM Vision Measuring Machine Suppliers Company – Manual vision measuring machine with metallographic systems – Chengli

China OEM Vision Measuring Machine Suppliers Company – Manual vision measuring machine with metallographic systems – Chengli Detail:

Parameters & Features

|

Model |

CLT-2010MS |

|

X/Y/Z measurement stroke |

200×100×150mm |

|

Z axis stroke |

Effective space: 150mm, working distance: 45mm |

|

XY axis platform |

X/Y mobile platform:Grade 00 cyan marble; Z axis column: cyan marble |

|

Machine base |

Grade 00 cyan marble |

|

Size of glass countertop |

250×150mm |

|

Size of marble countertop |

400×260mm |

|

Bearing capacity of glass countertop |

15kg |

|

Transmission type |

X/Y/Z axis: Linear guides and polished rods |

|

Optical scale |

0.001mm |

|

X/Y linear measurement accuracy (μm) |

≤3+L/200 |

|

Repetition accuracy (μm) |

≤3 |

|

Camera |

HD Industrial Camera |

|

Observation method |

Brightfield, oblique illumination, polarized light, DIC, transmitted light |

|

Optical system |

Infinity Chromatic Aberration Optical System Metallurgical objective lens 5X/10X/20X/50X/100X optional Image magnification 200X-2000X |

|

Eyepieces |

PL10X/22 Plan High Eyepoint Eyepieces |

|

Objectives |

LMPL infinity long working distance metallographic objective |

|

Viewing Tube |

30° hinged trinocular, binocular: trinocular = 100:0 or 50:50 |

|

Converter |

5-Hole Tilt Converter with DIC Slot |

|

The body of the metallographic system |

Coaxial coarse and fine adjustment, coarse adjustment stroke 33mm, fine adjustment accuracy 0.001mm, With coarse adjustment mechanism upper limit and elastic adjustment device, Built-in 90-240V wide voltage transformer, dual power output. |

|

Reflective lighting systems |

With variable market diaphragm and aperture diaphragm and color filter slot and polarizer slot, With oblique lighting switch lever, single 5W high-power white LED and continuously adjustable brightness |

|

Projection lighting systems |

With variable market diaphragm, aperture diaphragm, color filter slot and polarizer slot, With oblique lighting switch lever, single 5W high-power white LED and continuously adjustable brightness. |

|

Overall dimension(L*W*H) |

670×470×950mm |

|

Weight |

150kg |

|

Computer |

Intel i5+8g+512g |

|

Display |

Philips 24 inches |

|

Warranty |

1 year warranty for the whole machine |

|

Switching power supply |

Mingwei MW 12V/24V |

Environment Of Instrument

1. Temperature and humidity

Temperature: 20-25℃, optimal temperature: 22℃; relative humidity: 50%-60%, optimal relative humidity: 55%; Maximum temperature change rate in the machine room: 10℃/h; It is recommended to use a humidifier in dry area, and use a dehumidifier in humid area.

2. Heat calculation in the workshop

Keep the machine system in the workshop operating in the optimum temperature and humidity, and the total indoor heat dissipation must be calculated, including the total heat dissipation of indoor equipment and instruments (lights and general lighting can be ignored).

1. Heat dissipation of human body: 600BTY/h/person.

2. Heat dissipation of workshop: 5/m2.

3. Instrument placement space (L*W*H): 3M ╳ 2M ╳ 2.5M.

3. Dust content of air

The machine room shall be kept clean, and the impurities greater than 0.5MLXPOV in the air shall not exceed 45000 per cubic foot. If there is too much dust in the air, it is easy to cause resource read and write errors and damage to the disk or read-write heads in the disk drive.

4. Vibration degree of machine room

The vibration degree of machine room shall not exceed 0.5T. Machines that vibrate in the machine room shall not be placed together, because the vibration will loosen the mechanical parts, joints and contact parts of the host panel, resulting in abnormal operation of the machine.

Power Supply

FAQ

How about the shipping fees?

Shipping costs depend on how you choose to get your goods. Air freight is usually the fastest but also the most expensive way. Sea freight is the best solution for bulk shipments. The exact shipping fee can only be given to you after we know the details of the quantity, weight and manner. Please contact us for more information.

Can you supply the relevant documentation?

Yes, we provide most of the documents, including the technical parameters of the equipment, theinstruction manual of the software and the instructional video, etc.

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of ''Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for China OEM Vision Measuring Machine Suppliers Company – Manual vision measuring machine with metallographic systems – Chengli , The product will supply to all over the world, such as: Slovenia, Boston, Montreal, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we have got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!