Vision Measuring Machine is a high-precision optical Vision Measuring Machine , which is widely used in the measurement of various precision parts.

IV. Features and Advantages

1. High precision: The Vision Measuring Machine has micron-level precision numerical control hardware and humanized operation software, which can achieve high-precision measurement.

2. Non-contact measurement: It avoids the errors and damage that may be caused by traditional contact measurement.

3. High degree of automation: The fully automatic Vision Measuring Machine can automatically complete the measurement operation, saving manpower and improving efficiency.

4. Versatility: By using the probe and laser group, the Vision Measuring Machine can achieve two-dimensional and three-dimensional geometric dimensions.

5. Easy operation: The digital Vision Measuring Machine thoroughly integrates various functions, making the operation easier and faster.

V. Application Fields

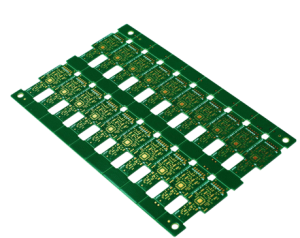

Vision Measuring Machine s are widely used in machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision hardware, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, computers, LCD TVs, printed circuit boards, automobiles, medical equipment, clocks and watches, instrumentation and other fields.

It is mainly used to measure the size and angle of parts that are difficult or impossible to measure with calipers and angle rulers.

VI. Use and Maintenance

When using the Vision Measuring Machine , pay attention to the following points:

1. The instrument should be placed in a clean and dry room to avoid contamination of the optical parts and rust of metal parts.

2. After using the instrument, it should be wiped clean and covered with a dust cover.

3. Lubricate the transmission mechanism and motion guide rails of the instrument regularly to keep it in good use.

4. The precision parts of the instrument such as the imaging system, workbench, optical ruler, etc. need to be precisely adjusted. Customers should not disassemble it by themselves. If there is any problem, notify the manufacturer to solve it.

Post time: Sep-27-2024