Video Measuring Machine Company – Professional Design China Automated Vision Measuring Machine APC300 – Chengli

Video Measuring Machine Company – Professional Design China Automated Vision Measuring Machine APC300 – Chengli Detail:

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Professional Design China Automated Vision Measuring Machine APC300, should you’ve any query or wish to place an initial buy make sure you will not wait to get hold of us.

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for , We offer the great variety of products in this field. Besides, customized orders are also available. What’s more, you will enjoy our excellent services. In one word, your satisfaction is guaranteed. Welcome to visit our company! For more information, please come to our website.If any further inquiries, please feel free to contact us.

Parameters & Features

|

Model |

SMU-3020EA |

SMU-4030EA |

SMU-5040EA |

|

X/Y/Z measurement stroke |

300×200╳200mm |

400×300╳200mm |

500×400╳200mm |

|

Z axis stroke |

Effective space: 200mm, working distance: 90mm |

||

|

XYZ axis base |

X/Y mobile platform:Jinan green marble; Z axis column: square steel |

||

|

Machine base |

Jinan green marble |

||

|

Size of glass countertop |

350×250mm |

450×350mm |

550×450mm |

|

Size of marble countertop |

460×360mm |

560×460mm |

660×560mm |

|

Bearing capacity of glass countertop |

25kg |

||

|

Transmission type |

X/Y axis: High precision cross drive guide and polished rod Z axis: High precision linear guide and screw rod |

||

|

Optical scale |

X/Y axis: High precision optical scale resolution: 0.001mm |

||

|

X/Y linear measurement accuracy (μm) |

≤3+L/200 |

||

|

Repetition accuracy (μm) |

≤3 |

||

|

Camera |

1/3″ HD color industrial camera |

||

|

Lens |

Auto zoom lens, optical magnification: 0.7X-4.5X, image magnification: 30X-300X |

||

|

Image system |

Image software: it can measure points, lines, circles, arcs, angles, distances, ellipses, rectangles, continuous curves, tilt corrections, plane corrections, and origin setting. The measurement results display the tolerance value, roundness, straightness, position and perpendicularity. The degree of parallelism can be directly exported and imported into Dxf, Word, Excel, and Spc files for editing which is suitable for batch testing for customer report programming. At the same time, part of and the entire product can be photographed and scanned, and the size and image of the entire product can be recorded and archived, then the dimensional error marked on the picture is clear at a glance. |

||

|

Image card: SDK2000 chip image transmission system, with clear image and stable transmission. |

|||

|

Illumination system |

Continuously adjustable LED light (Surface illumination +contour illumination), with lower heating value and long service life |

||

|

Overall dimension(L*W*H) |

850×1500×1600mm |

950×1600×1600mm |

1050×1700×1700mm |

|

Weight(kg) |

150kg |

200kg |

250kg |

|

Power supply |

AC220V/50HZ AC110V/60HZ |

||

|

Computer |

Special host |

||

|

Display |

Philips 24 inches |

||

|

Warranty |

1 year warranty for the whole machine |

||

|

Switching power supply |

Mingwei MW 12V/24V |

||

Product Description

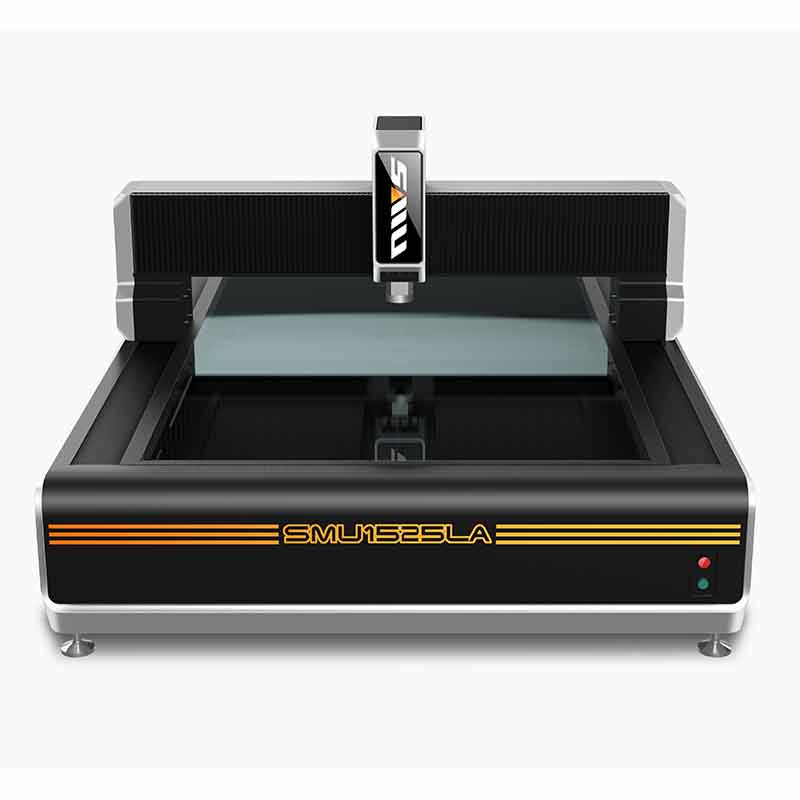

The automatic vision measuring machine is suitable for large-scale two-dimensional dimension measurement of precision electronics, hardware, semiconductors, plastics, precision molds and other products. In the case of product positioning, we only need to edit one program for the same product to achieve fully automatic batch inspection. Its higher precision and measurement efficiency are ten times that of manual vision measuring machines, thus saving labor costs and time costs, and the fully automatic measurement method avoids human operation errors and realizes truly intelligent manufacturing.

Working Environment of Instrument

1. Temperature and humidity

Temperature: 20-25℃, optimal temperature: 22℃; relative humidity: 50%-60%, optimal relative humidity: 55%; Maximum temperature change rate in the machine room: 10℃/h; It is recommended to use a humidifier in dry area, and use a dehumidifier in humid area.

2. Heat calculation in the workshop

Keep the machine system in the workshop operating in the optimum temperature and humidity, and the total indoor heat dissipation must be calculated, including the total heat dissipation of indoor equipment and instruments (lights and general lighting can be ignored).

1. Heat dissipation of human body: 600BTY/h/person.

2. Heat dissipation of workshop: 5/m2.

3. Instrument placement space (L*W*H): 3M ╳ 2M ╳ 2.5M.

3. Dust content of air

The machine room shall be kept clean, and the impurities greater than 0.5MLXPOV in the air shall not exceed 45000 per cubic foot. If there is too much dust in the air, it is easy to cause resource read and write errors and damage to the disk or read-write heads in the disk drive.

4. Vibration degree of machine room

The vibration degree of machine room shall not exceed 0.5T. Machines that vibrate in the machine room shall not be placed together, because the vibration will loosen the mechanical parts, joints and contact parts of the host panel, resulting in abnormal operation of the machine.

Power Supply

AC220V/50HZ

AC110V/60HZ

Product detail pictures:

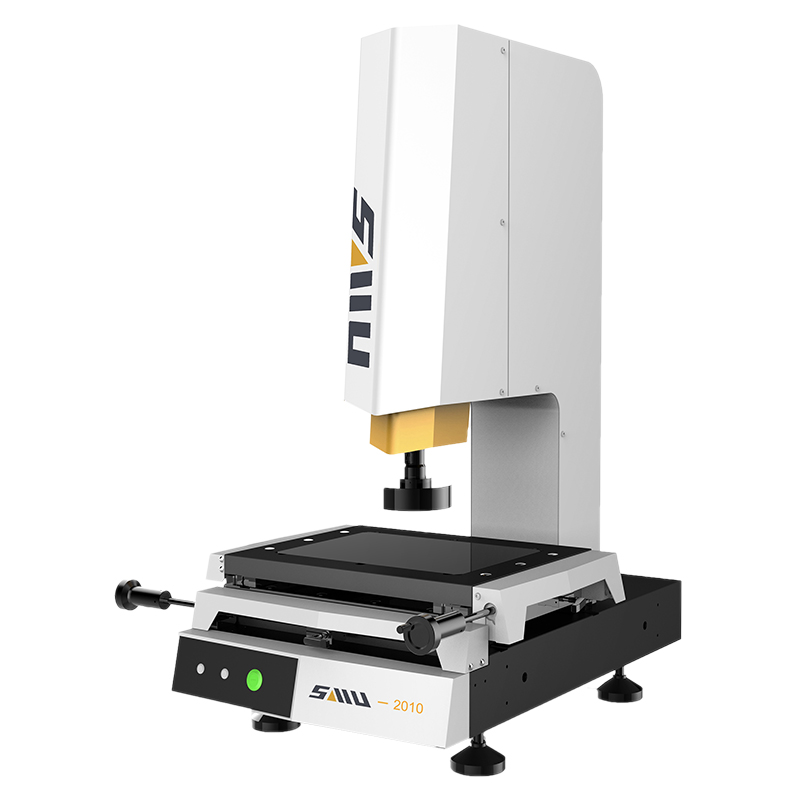

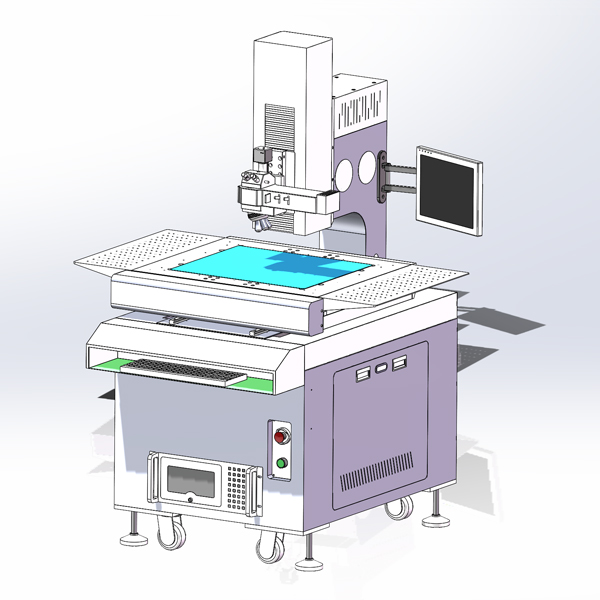

Related Product Guide:

The business keeps to the operation concept "scientific management, premium quality and efficiency primacy, customer supreme for Video Measuring Machine Company – Professional Design China Automated Vision Measuring Machine APC300 – Chengli , The product will supply to all over the world, such as: Belize, Belarus, Sevilla, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.